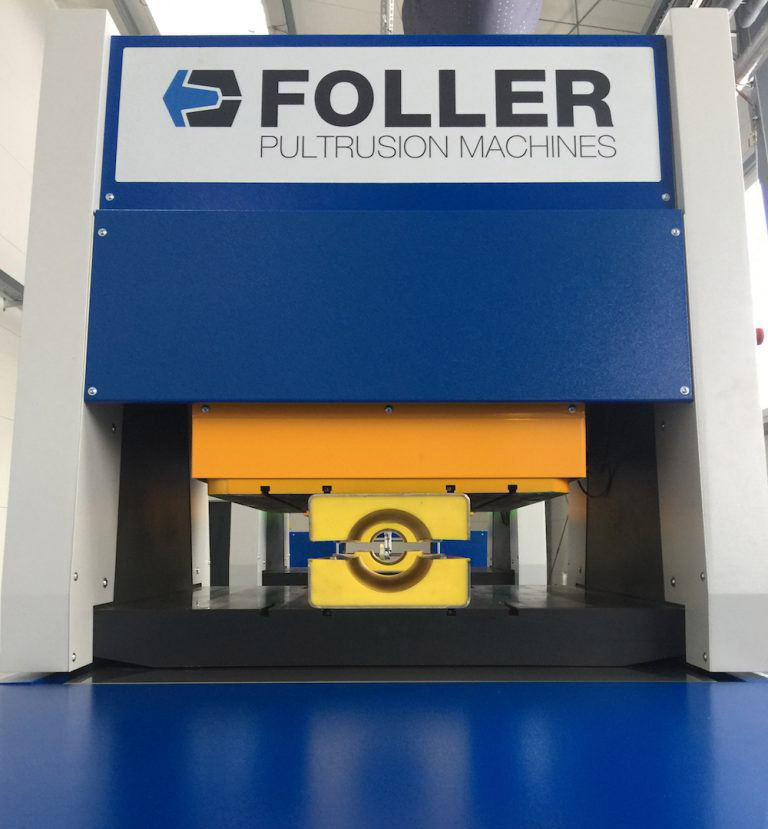

FOLLER s.r.o.

SERVOELECTRIC PULTRUSION MACHINES

FOLLER, s.r.o. was founded by Dr. Bronislav Foller in 1998 in Brno, Czech Republic. FOLLER company develops, designs and builds servoelectric pultrusion machines. He leads research and development in the field of pultrusion technology, ultrasound-assisted pultrusion, microwave-assisted pultrusion, pullwinding pultrusion technology, injection pultrusion and thermoplastic pultrusion technology. The company follows the latest trends in drive technology, automation technology, and industry 4.0 technology.

Products

FOLLER specializes in the design and manufacture of CE certified pultrusion machines and equipment for pultrusion technology.

Our company offers complete technology solutions to companies outside the composites industry and full technology package to start – up companies. These services can include: assistance with product design of profiles and tooling design, product prototyping and testing materials.

We can provided testing by thermal analysis as DSC – Differential Scanning Calorimetry, TGA – Thermo

gravimetry, TMA – Thermo mechanical analysis, DMA – Dynamic Mechanical Analysis, Rheology of matrix system and mechanical testing of polymer matrix composites in our research laboratory.

We can supply pultrusion machines with precision servo electric drive with very high energy efficiency.

In our machines, we use top mechanical and electrical components from European, American and Japanese manufacturers. Machines has very compact design without folder cover of motion mechanism.

Operation control PC panel with Touch Screen Display 19“ with Start, Stop and Safety stop buttons in the

compact steel panel with wireless transfer technological system parameters.

We offer control systems SIEMENS, SCHNEIDER ELECTRIC, B+R Automation, TG DRIVES and HITACHI

| MACHINE | R 40 | R 60 | R 80 | R 120 | R 160 | R 240 | |

| Pulling Force in tons | t | 4 | 6 | 8 | 12 | 16 | 24 |

| Pulling Force | kN | 40 | 60 | 80 | 120 | 160 | 240 |

| Profile Clamp Force | kN | 100 | 150 | 200 | 300 | 400 | 600 |

| Standard clamping length | mm | 500 | 500 | 600 | 600 | 700 | 700 |

| Pulling and Cutting Dimensions | |||||||

| Width | mm | 300-400 | 400-600 | 600-800 | 800-1200 | 1000-1600 | 1200-1600 |

| Standard height | mm | 130 | 180 | 180 | 180 | 240 | 300 |

| Pulling Speed [min. - max.] | |||||||

| Minimum speed | m/min. | 0,04 | 0,04 | 0,04 | 0,04 | 0,04 | 0,04 |

| Maximum speed | m/min. | 3 | 2 | 2 | 2 | 1,5 | 1,5 |

| Die Heating Zones | Stand. | 3 | 4 | 6 | 6 | 6 | 6 |

| Self-tune temperature PID controllers | Option | 6 | 24 | 24 | 24 | 24 | 24 |

| Electric power Control + Motion | kW | 5 | 5 | 8 | 10 | 10 | 14 |

| Heating zones power | kW | 12 | 16 | 24 | 24 | 24 | 24 |

| Utilities for standard machines | |||||||

| Electric power | kVA | 15 | 20 | 30 | 30 | 30 | 40 |

| Compressed Air 6oo kPa | m3/min. | 0,03 | 0,04 | 0,04 | 0,05 | 0,05 | 0,05 |

We can supply standard pultrusion machines to complete turnkey pultrusion lines including

- Technological transfer of Know-How for Profile assessment, reinforcement design and resin matrices.

- Design of the technological procedure for the production of the profile.

- Recommendation of the most suitable machine.

- The construction of the pultrusion mold and its cleaning and maintenance procedure.

- Equipment for mixing resins.

- Specifications of raw materials .(resins, additives, hardeners, color pigments and fillers, functional additives and supplier recommendations.

- Manpower requirements.

Pultrusion machine with

- Flying cut saw

- Supports for unrolling veils, mats and fabrics

- Infrared furnaces and thermoplastic systems

- Online data collection system and graphic displays

- Takeout tables

- Laboratory and test equipment

- Commissioning and training Technology/know-how

Production of special pultrusion lines for the production of carbon lamellas for aircraft structures and the construction industry

Solution for environments with the risk of explosion and electric short circuit due to contamination of the air with carbon fibers in the pultrusion process.

The lines are equipped with tight covers and secured by a slight negative pressure in the space of the carbon roving spools.

Production of pultrusion lines for mass production of composite reinforcements for concrete.

Reinforcements for concrete produced by classic pultrusion technology in pultrusion form Concrete reinforcement produced by pultrusion without a mold with an impregnation pressure zone by curing in a continuous curing oven

Corporate R&D in pultrusion since 1998

- 1998 Laboratory caterpillar pultrusion machine with precise measurement of tensile force.

- 2001 Microwave hardening of profiles.

- 2002 Ultrasound-assisted pultrusion of thin-walled profiles.

- 2004 High-capacity servo-electric pultrusion machine for the production of standard profiles.

- 2010 Ceramic pultrusion technology. For the production of profiles based on geopolymer matrices.

- 2016 Servo-electric PULWINDING machine for high-capacity continuous production of composite pipes.

- 2019 Servo-electric high-capacity machine for continuous 24/365 production of profiles with a requirement for color stability and color etalon according to RAL.

- 2021 Construction of a semi-automatic mixing station with an integrated scale, recipes and data report to an external station.

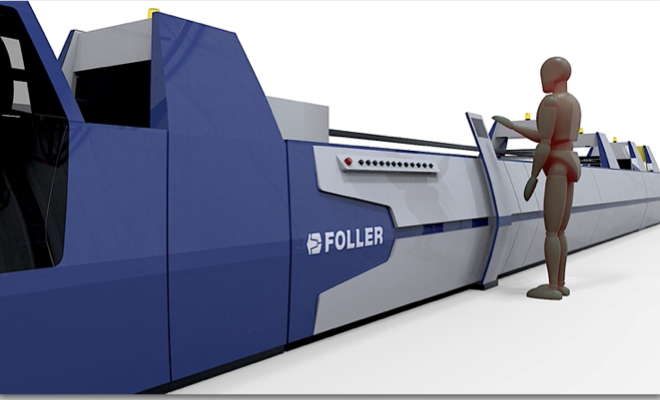

NEW Model 2023 Pultrusion machine

High-performance pultrusion machine for precise profiles. Continuous monitoring of the curing of the composite material, storage of technological data in a nonmanipulable form in the machine’s memory. Online report to the control center. Continuous printing of profile identification and parameters according to customer requirements.

Partners

The main partner for industrial automation and drives of pultrusion machines and equipment

SIEMENS s.r.o.

Olomoucká 3419, 618 00 Brno, Czech Republic

The main partner for creels for unrolling the fibres – tangential unwinding carbon rovings

TEXMER GmbH & Co. KG

Gerhardsweg 7 D-36100 Petersberg-Böckels

The main partner for the production of machine frames and machine assembly

Strojírny Prostějov, a.s.

Kojetínská 3700/5, 796 01 Prostějov, Czech Republic

The main partner for the production of Tools and Pultrusion Die, Material and Heat treatment

Voestalpine High performance Metals CZ s.r.o.

Průmyslová 591/ 1, 682 01 Vyškov, Czech Republic

The main partner for R&D of epoxy composite materials, epoxy resins and matrix

SYNPO a.s.

S. K. Neumanna 1316, 532 07 Pardubice, Czech Republic

The main partner for R&D of polyester and vinyl ester composite materials, resins and matrix

SCOTT BADER EASTERN EUROPE S.R.O.

1. máje 97/25, Jeřáb 460 07 Liberec, Czech Republic

The main partner for the automation and programming of technological machines

TG DRIVES, s.r.o.

Olomoucká 1290/79, 627 00 Brno, Czech Republic

Contacts

FOLLER, s.r.o.

Charbulova 292/10

618 00 Brno

Czech Republic

Phone: +420 775 912 947

E-mail: foller@foller.eu

Company ID: 255 49 677

‘VAT Number: CZ25549677

The company is registered in the Commercial Register

kept by the Regional Court in Brno, Section C, Insert 32 645